BLOG AND NEWS

Additional Testing Techniques to Measure Chromium Coating Quality

In the second installment of our blog series exploring testing techniques for assessing chromium coating quality, we will delve into microstructural analysis, porosity testing, chemical composition analysis, and roughness measurement. These testing techniques,...

Five Testing Techniques to Measure Chromium Coating Quality

Among its various forms, including Electrolizing® TDC and ME-92® Biochrome, Armoloy thin dense chrome coatings are renowned for their impressive wear resistance and minimal dimensional impact. Ensuring the highest quality of these coatings is not a matter of chance;...

The Increasing Importance of Thin Dense Chrome in the Food Processing and Packaging Industry: An In-Depth Analysis

Thin dense chrome (TDC), a uniquely specialized functional coating, is celebrated for its unrivaled hardness, impressive wear resistance, and exceptional corrosion protection properties. Its robust attributes make it an ideal selection for various components and...

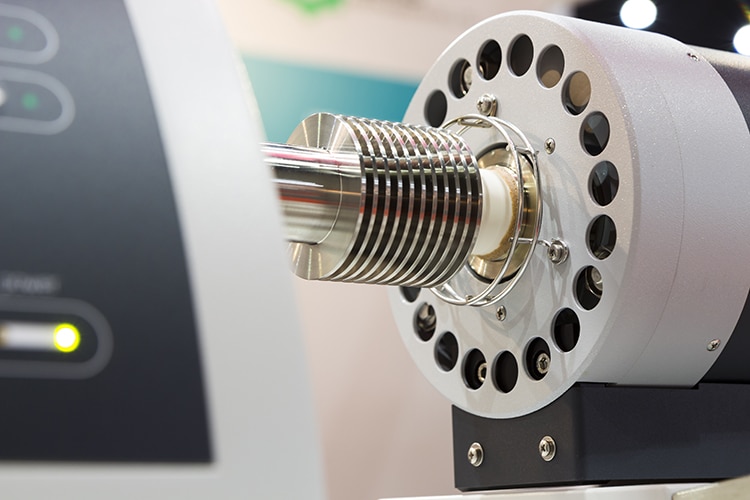

Protecting Performance: Thermal Expansion and Chromium Coatings

Thermal expansion is an important — and complicated — phenomenon to consider when designing or modifying industrial applications. A physical property observed in solids, liquids, and gases, thermal expansion occurs when the volume of the material changes in response...

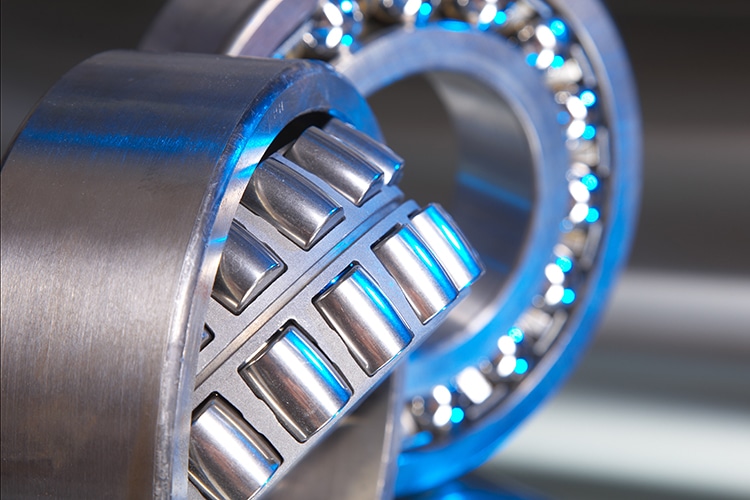

Understanding Rolling Contact Fatigue: Causes, Mechanisms, and Prevention

In our series on fighting metal failures, we’ve provided an overview of the different types of corrosion and abrasion. Now, we’ll examine rolling contact fatigue's role and impact on metal machinery and components. Rolling contact fatigue is a specific mode of metal...

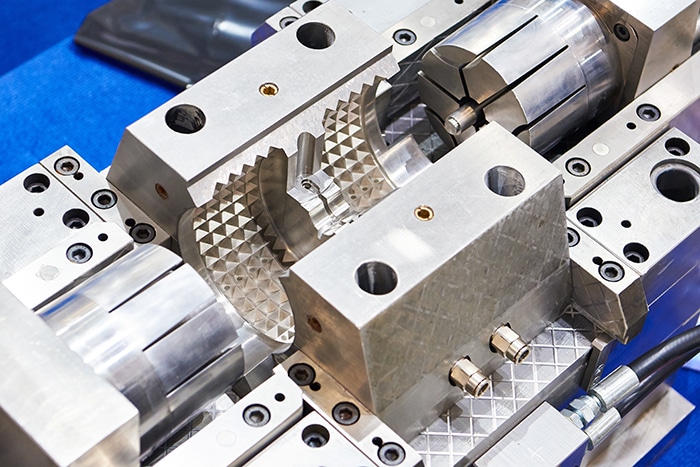

Protecting Component Shapes While Preserving Form and Function

The shape of a component is far more than mere aesthetics; it serves as the foundation upon which functionality, performance, and overall system efficiency are built. Component shapes directly influence behavior, interactions with other parts, and ability to meet...

The Real Cost of Metal Failure

From injury and loss of life to environmental and reputational damage, the cost of metal failure is devastating on a number of fronts. Corrosive metal failure and friction were at play in two recent high-profile accidents; in these events, the final bill is still...

Reducing Energy Consumption with Thin Dense Chrome

From the Pacific Gas and Electric Company groundwater pollution in Hinkley, California to the chromium spill at the Fairbanks Morse Engine facility in Beloit, Wisconsin, hexavalent chromium contamination due to inadequate process controls and oversight is...

The Environmental Benefits of Thin Dense Chrome Plating

The hazardous waste, fumes, and health risks associated with hexavalent chrome plating are well-publicized. Rarely, however, do we hear about the macro-environmental benefits of thin dense chrome (TDC), specifically around reducing friction and energy consumption,...

From Pipe Corrosion to Bearing Friction: Prevent Metal Failure with TDC

In 2022, Electricité de France (EDF), one of the world’s largest electricity producers and distributors, was forced to halt more than half of its nuclear fleet — leaving most of Europe, already heavily reliant on natural gas, in an energy crisis during a time of...